Current position:Home - Vision Applied AOI - Printing Sample Auto Checker

Product Name:Printing's Sample AutoCheck Device

The AutoCheck provides fast, accurate printing automatic alignment and detection scheme, no need to spend a lot of time to manual detection. To complete the automatic inspection of printing errors and defects in the prepress process, prevent to cause the printing waste. AutoCheck compatibility of electronic document (such as BMP, JPG, PDF, TIF, PNG format) and all kinds of printing materials. At the same time, can make the same type of electronic document or different types of electronic document (such as the PDF template file and BMP image file) ...

- Descr

- Para

- Down

- Instruc

1. Basic Functions and Features

(1) AutoCheck can be compared with the standard sample, detect different from standard proof. Including the stencil printing, deep, shallow printing etc.. It can measure the distance between the text.

(2) has a high detection accuracy, and the system operation and maintenance is simple, stable operation;

(3) proof engineering can be repeatedly used, easy management: every product can be put into a standard template;

(4) AutoCheck is easy to use and operation, intuitive and fast. If matching the output statements printing function and printer hardware, can be directly printed output results. Not only can reduce the match time, and can provide the reliable quality assurance, reduce waste, to win the trust of customers.

2. Features and Characteristics

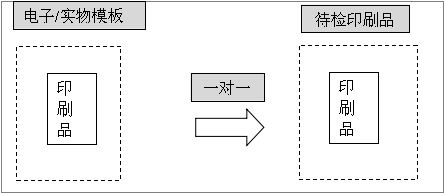

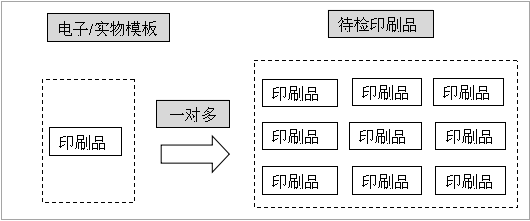

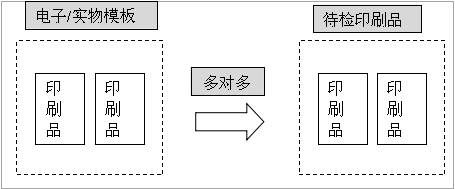

(1) in support of one to one, one to many, many to many detection.

1) One to One:

2)One to Many:

3) Many to Many:

(2) DeltaE (E) color detection, ensure the detection of image with the standard model of color change in a certain range;

(3) availability modeling. The wizard pattern guide users to build template, each product can be put into a standard template;

(4) the bar code identification module (optional module): testing code can be read correctly, and check the bar code printing quality. Support bar code and two-dimensional code;

(5) extract function of intelligent region. Graphics and text area identification, and a "magic wand" region extraction, automatic extraction of similar regional Unicom a point color, improve the modeling speed and quality;

(6) can be used for local deformation correction;

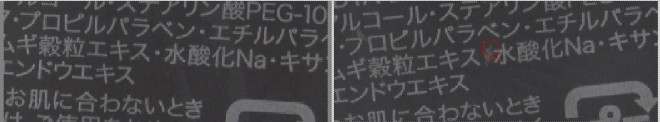

3. the pciture style of sample check results:

|

|

|

Item Name |

Technolofy Reference |

| Maximum Check Area | A4 (297×210mm) |

| Maximum Resolution | 600dpi (0.04mm/pixel) |

| Check Time | <1 Minute |

| File Format | BMP, PNG, TIFF, JPG,PDF |

| Marterial Type | Printing, film, sheet, plate |

| Check Type | Digital files and digital file;Digital files and printing; Printing andPrinting; |

| Defect Type | Stencil printing, deep, shallow printed, hyphenation, words, dirty points, foreign body, misregister, oblique, damage etc.. |

| Check Acurracy |

Defect area >0.02mm^2

The accuracy of size measurement >0.15mm |

Because the instrument with a console, The Instrument has no installation,and can be moved,.

中文版

中文版 English

English