Current position:Home - Vision Applied AOI - LCD AOI Devcies

Product Name:BW LCD AOI Device

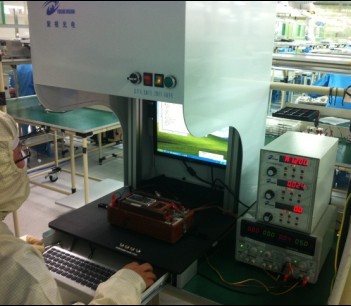

Focus 500 LCD AOI is a combination of LCD black and white screen production shipment quality requirements, after in-depth investigation and extensive and repeated testing is developed, and through continuous upgrading and improvement, has become many LCD manufacturers to black and white screen "machine QC". Equipment for the purpose is to improve the quality and efficiency of LCD manufacturers of products, enhance the manufacturers of automation, reducing labor intensity and density detection, reduce man-made uncontrollable factors, improve product quality and technology level。

- Descr

- Para

- Down

- Instruc

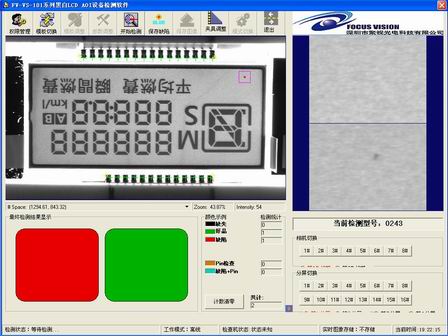

(1)The detection precision is high:stabledetection of 0.1mmpinhole defects,fullymeet the high-end customerdelivery requirement,the conventional detectionaccuracy of 0.15mm;

(2)The detection efficiency is high:two pieces ofproductscan supportadetection,fullyimprove the efficiency of detection.Such as the use ofequipment CH seriesautomaticturntable structuredesign ofthe machine,can make full use ofergonomicprinciples andman-machinemutualwaiting time,which makes the detectionefficiency is high,man-machinecoordination;

(3)According to the customerto detectscreenmax widthandaccuracy requirementsflexibly select1-45000000high-resolutionindustrial camera;

(4)Byindustrial camera,imageacquisitioncard,the advancedhigh resolutioncameraand other components,detectionof high stability;

(5)Optionaltotal reflection LCMmodule LEDforeground light sourcefordetecting highlifewithoutbacklightdetection;

(6)Byremoving dustinterferenceimaging and image processingtechnology,reduces the equipmentofLCDcleanexcessive demands,improve the detection efficiency;

(7)For the LCDbare glassdetection,optionaluniquesinglefixturedesigncan support multipleuniversal fixtureproduct models,the fixtureconfigurationof machine visionforLED backlight,as long as the replacement ofa circuit board,afixturecansupport varioustypes of products,to avoidaproduct modelatest fixture,bring aboutwaste andthe cost of managementon thetrouble;

(8)The high precision LCDscreen currentintelligent monitoroptionalwe design and manufacture,automatic matchingand AOIequipment,exception monitoringLCDscreen current,to make up for lack of AOIpicture can nottestthe abnormal currentbut the picture isnormal.At the same time,the currentintelligent monitorcanwork independentlyfrom the AOIdevice,used forartificial turningcontrol screenLCDscreen currentabnormal orexceed the standardalarm;

(9)Of various types ofproduct testing:supportmultiple types ofproduct modeling,modelingsimple,to achieve a variety ofmodelsof different sizes,specifications of thedetection ofLCD/LCM;

(10)Automatically set thedetection region:the user can according to their ownneeds to set/ shieldingcertain areas,flexible customization.

(11)The detection processin one time,and theLCD electrical measurementmachineor LCMautomaticscreen turningfixture drivencommunication,a set ofequipment can beconnected to the LCDelectrical measurementmachine can also bedirectly connected with LCMdriving fixture,doa set of equipmentmultiplexing LCDand LCM detection;

(12)Can supportadetection ofgrainproducts,fully improve equipmentefficiency;

(13)The detection resultsoutputwithsound,light alarmand displayin various forms,is convenient for manualconfirmation;

(1)Detected objects:field type,dot matrixTN,STN,HSTN,FSTN;

(2)Detection process:patchLCD andpatchafter LCD(including COG),LCM;

(3)Of various types ofproducts:total reflection,transflective,full penetrationand other typesof products;

(4)Detection index:

1)The detection speed:image acquisitionand detectiontime of eachscreen /camerais less than 150ms(manualfixturecommunicationtimeslice,the other),for generalskilled operators,dualcameradualparticlesinglescreen detectionLCDsemi-finished products,equipment usingautomaticturntable structureof double cameraconfiguration detectionspeedper hourcan reach700850PCSSseries equipment,ordinarydoublecameraconfiguration detectionspeedper hourfor450550PCS;

2Types of defectsdetection: lack ofplanning),multiplerow,row,pinhole,leakage ofinternal contamination,contrast,Pinroot numbercheckand clearance measurement;

3) The highestdetection accuracy ofmeasurement accuracy of 0.1mm(through softwarecontrol);

4)The measurement precisionis 0.15mm,2 camerasmaximum detectionsize: 260mm *100mm(180mm× 135mm),4 camerasmaximum detectionsize: 500mm *100mm(260mm* 180mm);

5)The missing rate: the ability ofstabledetection:

Lack ofplanning,multiplerow,row:zeroleakagedetection

Internal contamination,pinhole:≤100 PPM

The false detection rate:≤ 3%

|

|

Equipment environment parameters and requirements:

(1) Voltage: AC 220 v;

(2) power: 500 w, equipped with LCD current detector 30 watt power consumption;

(3) Electrostatic electrostatic eliminating measures: products might mistakenly identified, on site can provide electrostatic eliminator or measures, using the ion fan, operator wearing esd bracelet;

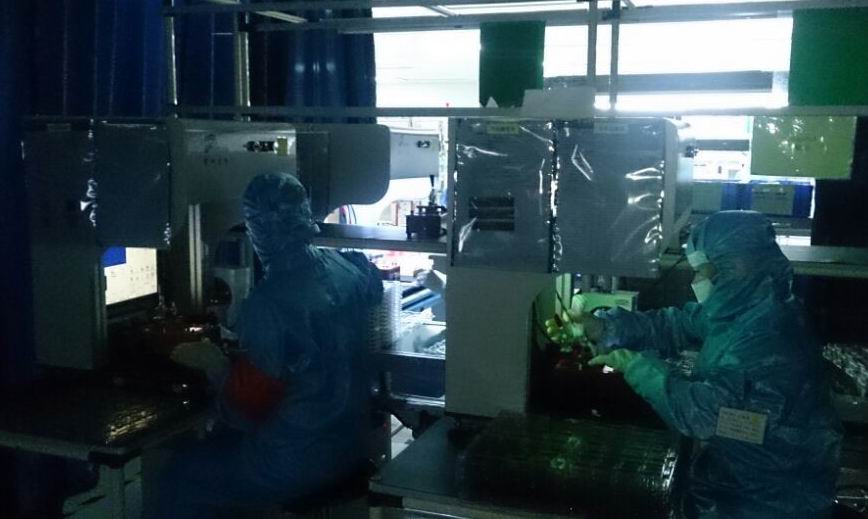

(4) clean environment requirements set don't need to put in more than thousand grade clean room work, if the level is lower than the hundreds, able to provide on site dust control measures and clean process;

(5) operating temperature range: 0 ~ 40 ℃;

(6) work range of relative humidity: 30% ~ 80% (not condensation);

中文版

中文版 English

English