Current position:Home - Vision Applied AOI - Silica Gel Appearence Auto Check

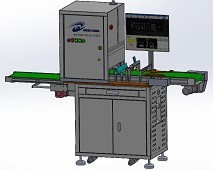

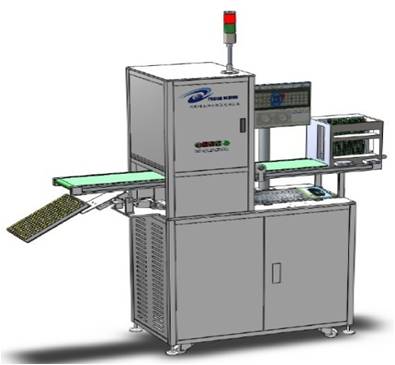

Product Name:Sillica gel Apperance Auto Checker

This equipment is the key of silica gel surface quality, stains, ink flying and color wrong are detected, through special optical imaging and image processing, with high precision and high efficiency image algorithm and visual technology, so as to find out the silica gel printing defects, stains, ink flying and color wrong problem.

- Descr

- Para

- Down

- Instruc

This equipment is designed to improve the quality and efficiency of detection of silica gel products manufacturers, improve production automation, reduce artificial detection strength and density, reduce man-made uncontrollable factors, improve product quality and technology level, win the trust of customers and the continued orders. At the same time, but also to improve the silica gel products delivery speed, greater capacity of silica production enterprises, in order to meet the more orders.

This Device has the following features:

1.Using two 5000000 pixel color high-resolution industrial camera and lens distortion industry, using advanced image detection algorithm and independent design and visual detection algorithm, detection function support color key, high precision, good stability;

2.Adopts unique design of high brightness color LED light source, long service life, automatically shut off the power source without detection, detection effect is stable and reliable;

3.Design scheme of the optical unit is unique, imaging effect is clear, overcome various material for polishing after the appearance of the reflector, drawing and uneven phenomenon, especially silica arc button inhomogeneous reflection phenomenon, detection effect is stable and reliable;

4.Has to eliminate static electricity and dust removal device, to prevent the equipment error conductive adhesive dust adsorption caused by;

5.Intelligent embedded control box independence rather than plate card is inserted in the computer control, improve the stability and reliability of the equipment;

6.Has good automatic partition function, the automatic warehouse quality products with unique design, the compact volume, mainly is the length and height of the small, save area;

7.Automatic feeding device optional, in order to improve the feeding efficiency and reduce labor intensity: artificial code good silica, for batch after testing, intermittently placed into batch equipment on the feeding device, which reduces the operator labor intensity due to frequent placing silica gel, while also ensuring the continuous equipment detection, high detection efficiency;

8.Ccan adapt to various types of silicone length is not a detection, various types of silicone products after entry can be stored for a long time to computer, detecting load can switch to detect the type of silicone products;

9.of the defects detected recently 3 products for real-time alarm and eye-catching mark, and counting statistics function;

10.test results are output with sound, lighting and display etc.;

1.The detection accuracy can be soft and hardware configuration according to user requirements, the maximum can reach 0.20mm, the stability of detection for 0.25mm;

2.Many types of product testing: support multiple models of silica gel product modeling, modeling simple, modeling time 10 minutes;

3.The system has self-learning function, and the learning process is simple in operation, with batch modeling, can be overcome and lead to error detection equipment for product consistency is poor:

Error Rate<5%,

Miss Rate <1/3000;

4.In normal skilled degree, detection efficiency can reach more than 1000PCS/ hours;

The device itself into one machine, no special installation, simply connect the power supply and air supply.

The power supply and air supply requirement:

1) 220V or 110V power supply;

2) >4Bar blowing gas;

中文版

中文版 English

English