Current position:Home - Vision Applied AOI - Remotor Appearance Checker Series

Product Name:Remotor Appearence Checker

This equipment is used to detect the surface of the remote controller and key surface quality, stains, ink flying and key-press wrong appearance quality, through special optical imaging and image processing, with high precision and high efficiency image algorithm and visual technology, so as to find out the remote screen printing defects, flying and key-press wrong etc. appearance quality problem.

- Descr

- Para

- Down

- Instruc

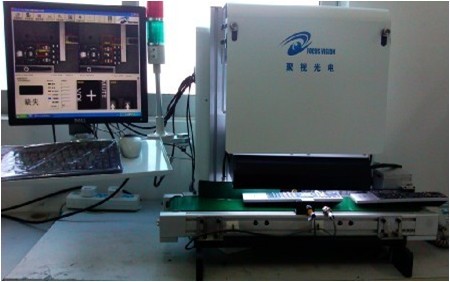

Model SM is a compact design of a device using detection box and the computer control box integration design, the SM-A model can be put on the table, but also by fixed installation located in customer site belt tension, SM-B model can support mobile, not fixed, can be directly used independently, but also can be used in on-site customer belt tension.

This equipment has the following features:

1. USES the high resolution camera and lens, USES the advanced visual inspection application algorithm and the analysis algorithm of image processing software, high detection precision, detection stability is good;

2. Adopts high brightness LED light warm color of unique design, automatic frequency detection, the service life is long, detection effect is stable and reliable;

3. Adopt unique optical unit design scheme of the remote control can be overcome on the surface of wire drawing, curved surface and curved keys of inhomogeneous reflective phenomenon;

4. Many type of product support multiple type remote control product modeling capabilities, easy modeling, the modeling can be completed within 15 minutes, and can save, support reuse, has realized the different size, various types of remote control test;

5. Testing of high efficiency and can run continuously 24 hours a day, never tired: for normal operation personnel, can be more than 1000 per hour;

6. After the test to detect the defects in real time alarm and eye-catching, and has the function of counting statistics;

7. Expect a photoelectric sensor automatic induction, responsive and reliable, able to adapt to different materials of remote control products. Test after test results output with a variety of forms such as sound, light and screen display;

1. The detection of silk screen printing, printing more wrong, incomplete, bearing, stain and ink;

2. The silk-screen printing offset detection and deflection, the user can be set according to the shipment allowed by the screen printing offset and deflection Angle;

3. Test the wrong buttons, color is wrong;

4. Precision can be software configuration according to user requirements, the highest detection accuracy can reach 0.20 mm, stable precision is 0.25 mm;

5. Under stable detection ability for 0.25 mm precision support remote maximum length is 300 mm, width can compatible with industry standard design of the remote control type;

6. Speed: artificial except loading time, each remote image acquisition and detection time is less than 1.5 seconds, for general skilled operators, equipment per hour the detection speed can reach 1000-1100;

|

|

|

|

Integration design, the equipment itself does not need special to install, simply environment and requirements can be installed as follows:

1. The power supply voltage: AC 220 v, grid stability;

2. Power: 500 w

3. Clean environment can provide on site dust control measures and clean process, in order to prevent the remote control has large dust impact test equipment;

4. The operating temperature range: 0 ~ 40 ℃; Working range of relative humidity: 30% ~ 80% (not condensation);

中文版

中文版 English

English